Shredding equipment is critical to the recycling process because it breaks down tough materials into smaller, more manageable parts before they are baled or made into a more convenient form for reuse. Different types of shredders are used for almost every kind of material that you can imagine; from rubber to plastic to metal and beyond.

Shred-Tech open_in_new

Location: Cambridge, ON

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications. Our Mobile and Stationary shredding solutions can handle a wide variety of materials including e-waste, plastics, paper, and metals. Contact us today or visit us online for more details.

Vecoplan, LLC open_in_new

Location: Archdale, NC

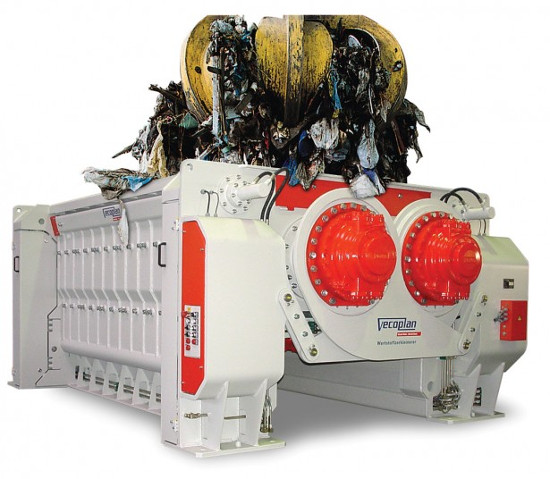

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions. Our innovative engineering means equipment for all needs: waste (including medical), metal, paper, tire, e-scrap, plastics, product/security destruction, construction and demolition (C and D).

Granutech-Saturn Systems open_in_new

Location: Grand Prairie, TX

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred! Our one-two and four shaft Saturn-Brand shredders can handle metal, plastic, tires, paper, and even automobiles! We can destroy and repurpose nearly any material that you have in your factory. Find out more by visiting www.granutech.com and view our shredder PRODUCT or APPLICATIONS page, or by calling us today.

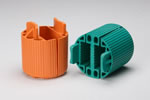

Because they are needed for so many different applications, shredders are manufactured in a wide variety of sizes and styles. Document destruction, for example, is much less heavy duty than metal shredding, so manufacturers create machines that meet the needs of each industry. One application that has seen a significant increase in shredding over the years is electronic scrap processing. Because there are now so many old electronic devices on the market, it is necessary to find ways to break them down and reuse their components.

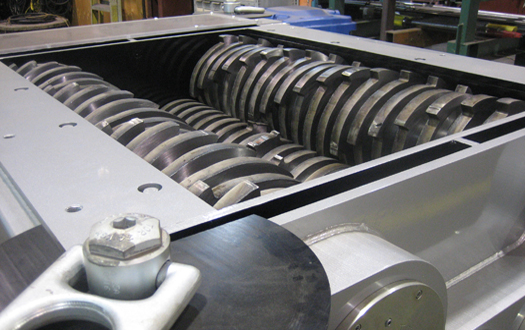

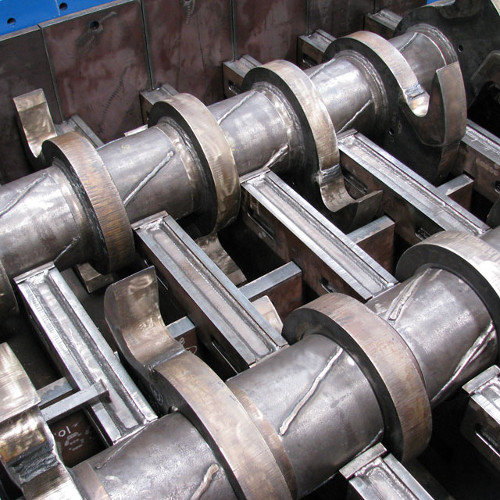

So, how do shredders work? Well, even though they are all a little different, the basic principle is the same across the board. There is a series of interlocking metal shafts with metal discs fitted along the entire length of the shaft at regular intervals. Theses shafts are usually located at the bottom of a hopper/feeding area and a motor powers their rotation. The discs on the shafts have sharp teeth that protrude at different points. These teeth are what grab onto objects being fed into the shredder and pull them in between the shafts where they separate into many tiny pieces. After the materials have been pulled through the shafts and broken up, they exit out of the bottom of the shredder into a bin or directly onto the floor of the facility where they are packaged or cleaned up.

Shredders can be built with only one shaft for smaller materials and light duty shredding tasks, or they can be built with up to four shafts for heavy duty applications and processing of bulk items. For instance, a shredder with two to four shafts would be used to shred tires since they are large and bulky until they are broken down. Having the ability to do this increases the speed of recycling and saves money. Without shredders it would be almost impossible to process and reuse much of the material that we are able to recycle today.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services