A growing need in manufacturing is the preservation of the environment by making use of waste materials. Every industry is doing its part to be ecofriendly by having repositories for recyclable waste. Though this may seem to be a major part of the process, the next step is to take the waste containers filled with recyclable materials and use separators to divide it into useable batches. A key aspect of the waste reclamation process is the arduous task of separating waste and useless items into organized groupings for use as raw materials. Read More.....

Eriez open_in_new

Location: Erie, PA

ERIEZ is a global manufacturer of an entire range of vibratory feeders and related machinery. We serve all the process industries, including food, chemical, pharmaceutical, ceramics, glass, packaging, metalworking, minerals processing and others. We also offer feeding machines so that all of your needs can be met. Please contact our company for a quote today!

Rodix, Inc. open_in_new

Location: Rockford, IL

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC open_in_new

Location: Newberg, OR

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

Hoosier Feeder open_in_new

Location: Knightstown, IN

If you are in need of quality vibratory feeders, we can help you out! At Hoosier Feeder, our philosophy is simple. We aim to put our customers first, get their requests right on the first try, communicate with them every step of the way, and deliver their products on time. We have experience working with a wide range of industries such as pharmaceutical, automotive, and food and beverage. For more information, please call or visit our website!

M & S Automated Feeding Systems, Inc. open_in_new

Location: Burnsville, MN

M&S Automated Feeding Systems creates parts feeders built and tested to each customer’s specific application. Fully equipped to design, fabricate and service a complete range of quality feeding equipment and specialized parts handling systems, including vibratory controls, conveyors, custom mechanisms, centrifugal feeder bowls, hoppers, vibratory inline feeders, sealing and vision systems.

Preparing Waste for a Separator

The job of separation begins with the collection of waste materials by waste management companies. Waste produced by paper and clothing companies is normally sent to a different collection point than that which is produced by heavy manufacturing.

Waste from heavy industrial manufacturing requires a more complex set of methods, which rely heavily on the use of separators to categorize and organize the many varieties of waste matter.

In the initial separation process, aluminum cans, shredded paper, and clothing are usually at the beginning and end of the process. These materials are already in a form to be sent on as raw materials for repurposing and reprocessing since they are not mixed with other components. In the case of larger products, such as cars, machines, equipment, and electronics, separators are necessary since these complex pieces of machinery contain several different forms of materials as part of their construction.

Before complex equipment can be sent on to a separator, they have to be crushed to form small bits and pieces. Crushing is completed by a shredder with huge metal teeth designed to tear into any item regardless of its size, dimensions, weight, shape, and composition. The shredding process produces a pile of mixed raw materials that can go through separators. In the separator process, the small bits and pieces are removed from the giant mass and placed in categories that can be used as raw materials.

The Separator Process

The metal bits from shredding contain ferrous or non-ferrous material, which are mingled together in a huge lump. When examining the massive pile, it may seem to be impossible to separate the individual metals. To that end, engineers in the recyclable machinery business have developed a variety of ways of using a separator to pull out metal particles using magnets. As the pieces of metal travel along a conveyor belt, a magnet, located above the belt, separates the ferrous pieces from the non-ferrous ones. After which, the ferrous metals are sent on for further processing.

The well-designed methods for separating metals do not solve the problem of separating non-ferrous and non-magnetic materials. A non-technical way for separating non-magnetic waste is by picking, a manual process, where separating, sorting, and categorizing waste materials is done by hand. As logical as it may seem, it is time consuming, labor intensive, and expensive.

Modern Separators

As the recycling industry has developed and grown, it has designed and engineered a variety of technologically advanced methods for separating and sorting waste materials. One of the more advanced of these processes is the optical sensor process that is designed to spot and remove certain materials. Programmed sensors identify the targeted materials, activate a mechanical arm or air jet that removes items from the conveyor belt.

Other separation methods involve the use of flotation, eddy currents, air classifiers, and screens. The recycling industry has a wide and varied number of choices for sorting what we may call garbage into raw materials for remanufacturing and reprocessing. They are constantly searching for ways that will make use of useless items.

The key to any waste management operation is the separation of reusable waste to be transformed into raw materials. This ongoing effort is another part of industry’s efforts to preserve the environment.

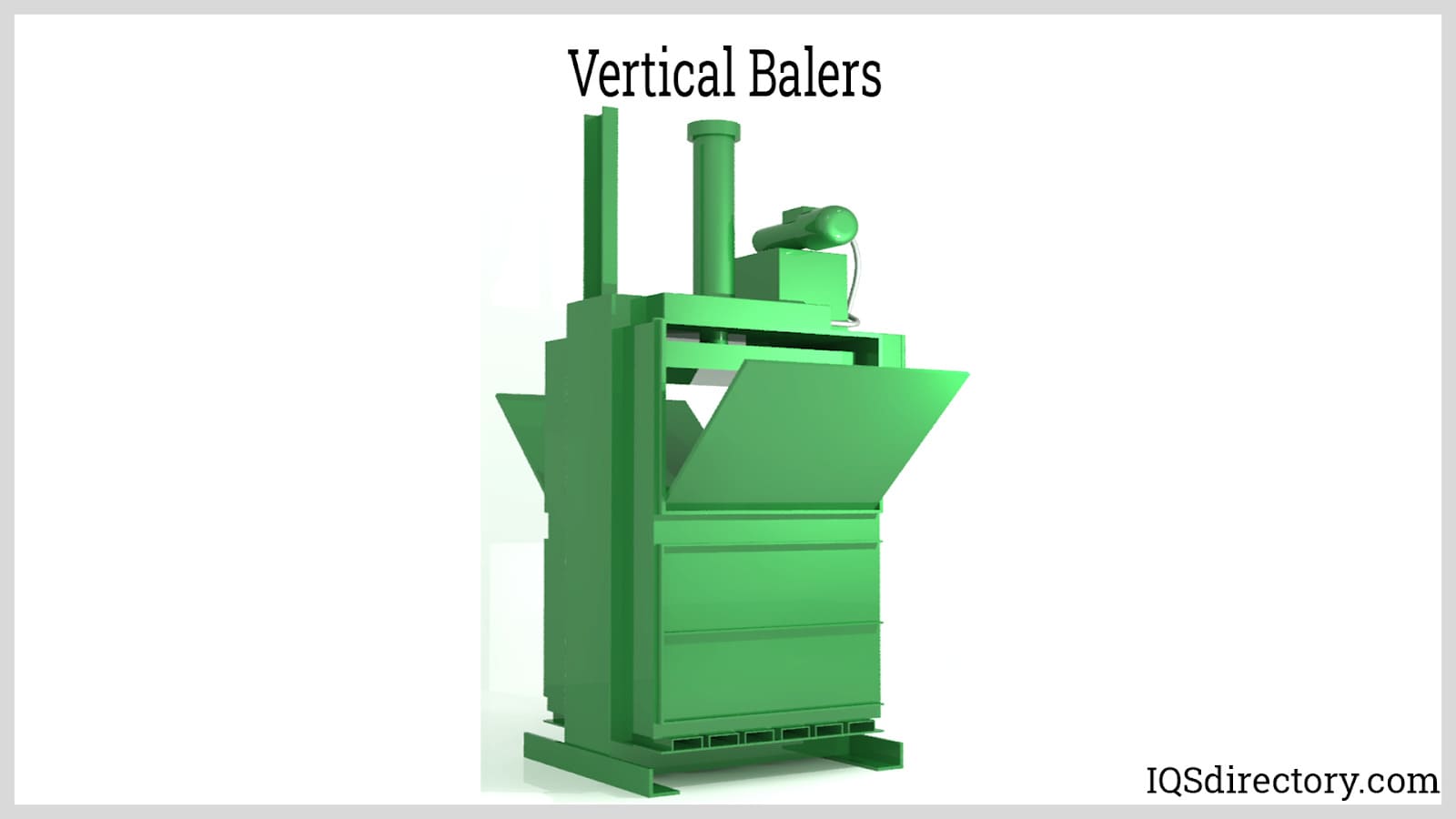

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services