In many recycling and recovery plants, scrap and waste materials are often stored in large piles to be processed at a later time. For these kinds of facilities, the use of a grappler is often the most effective method for introducing these piled materials into the recycling and recovery process. Read More…

SSI Shredding Systems, Inc.

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions. Our innovative engineering means equipment for all needs: waste (including medical), metal, paper, tire, e-scrap, plastics, product/security destruction, construction and demolition (C and D).

Wilsonville, OR | 503-682-3633

Shred-Tech

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications. Our Mobile and Stationary shredding solutions can handle a wide variety of materials including e-waste, plastics, paper, and metals. Contact us today or visit us online for more details.

Cambridge, ON | 800-465-3214

Vecoplan, LLC

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Archdale, NC | 336-298-8722

A grappler is a piece of material handling equipment which can take on many shapes; however, all grapplers serve the same purpose of picking up and maneuvering large quantities of scrap materials. This kind of equipment is generally attached to the long boom or arm of a piece mobile heavy machinery, much like a backhoe. One of the most common types of grapplers is the claw grappler. The aptly named claw grappler has a series of curved metal arms that look like claws. This machine is controlled by an operator who can open and close the claw to lift and release loose material. For recycling plants where metal is being handled, it’s quite common to use a scrap handling magnet, in place of a claw grappler, since this can easily pick up scrap metal using magnetic force.

Grapplers typically use either hydraulic or electric force to open and close their lifting mechanisms. These lifting arms need to be very strong in order to clench heavy materials and safely lift heavy objects that could be found among the debris. A grappler can typically be purchased and added as an attachment to a backhoe or a similar piece of heavy equipment. This versatility keeps equipment costs low while still giving recycling facilities the implements they need to handle high volumes of recycled material. On the other hand, they can also be purchased as part of a complete material handling vehicle. Many material handling equipment manufacturers design and supply grappling vehicles specifically constructed for use in recycling facilities. These types of equipment are equipped with stabilizers to keep the vehicle from tipping over when lifting heavy materials.

Scrap Handling Magnets

A scrap handling magnet is very similar to a grappler but uses electromagnetic forces to attract and hold objects instead of mechanical force. Scrap handling magnets consist of an electromagnet connected to a chain on the end of a hydraulic arm that can raise and lower it. Scrap handling magnets come in a variety of sizes, but they are usually round and the top portion is encased in a strong metal body to protect the magnet and hold it firmly in place during use. The magnets used to lift scrap metal can be powerful enough to pick up thousands of pounds at a time, and they are frequently used in facilities that specialize in metal recovery.

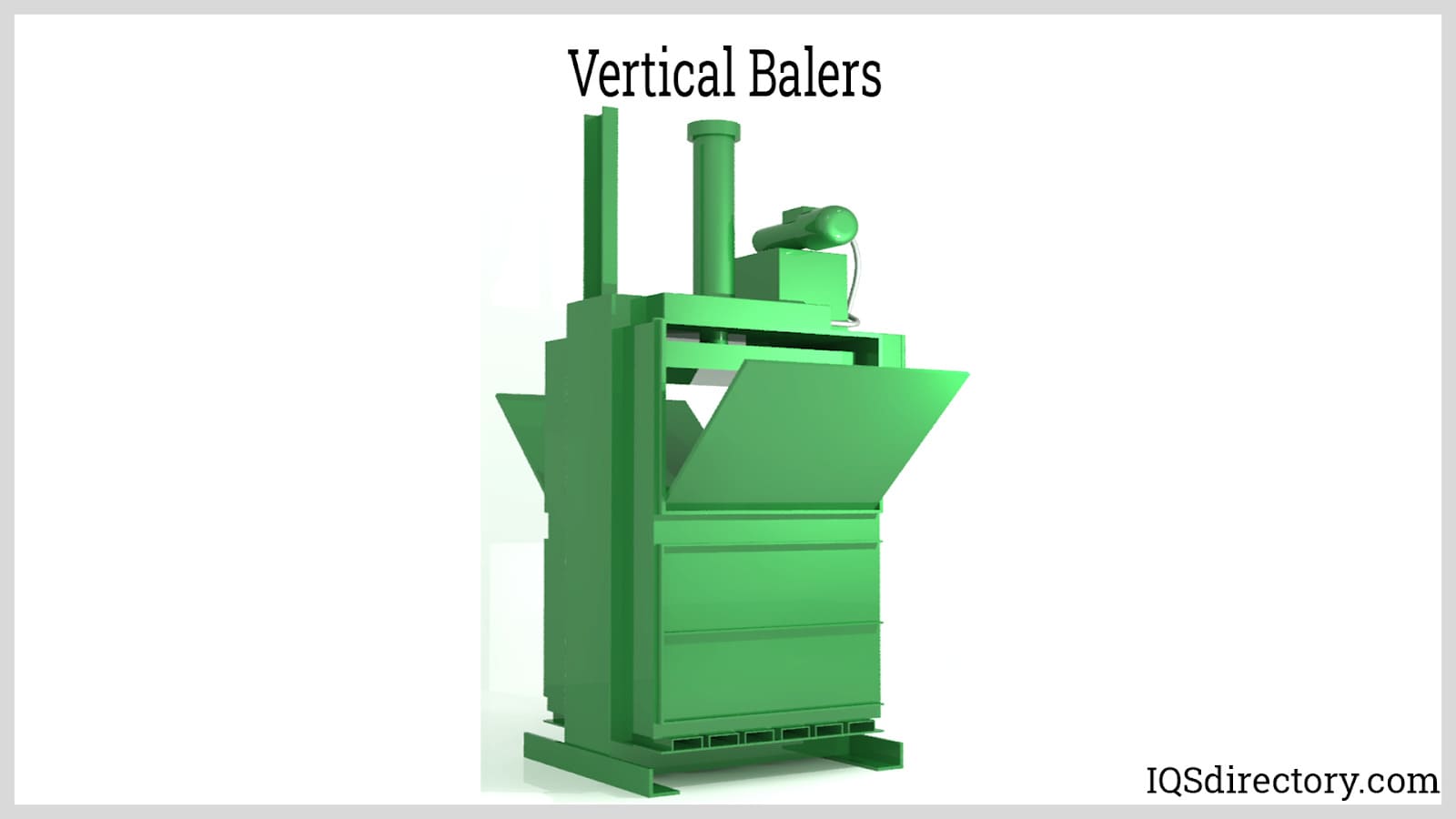

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services