Recycling Equipment

The recycling process starts with material collection. A waste management company gathers recyclables from homes, commercial dumpsters, and industrial facilities using trucks. These materials are then transported to a recovery center for processing.

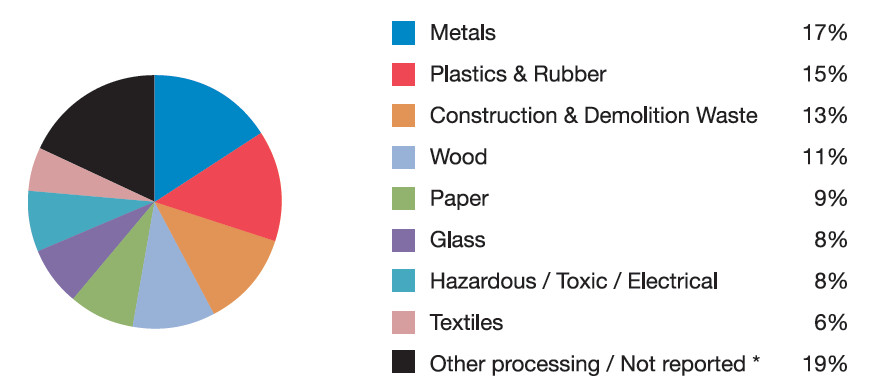

Repurposing used materials to avoid landfills is essential for reducing environmental impact and conserving resources. An efficient recycling process allows residential, commercial, and industrial locations to dispose of, sort, and reuse materials such as metals, plastics, rubber, construction waste, wood, paper, cardboard, glass, and textiles.

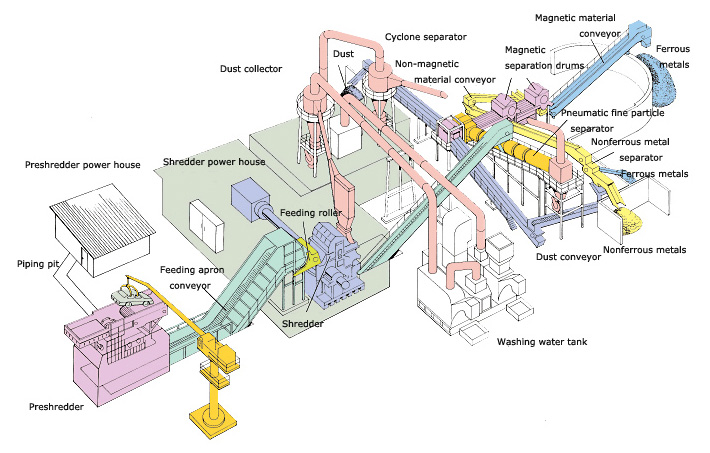

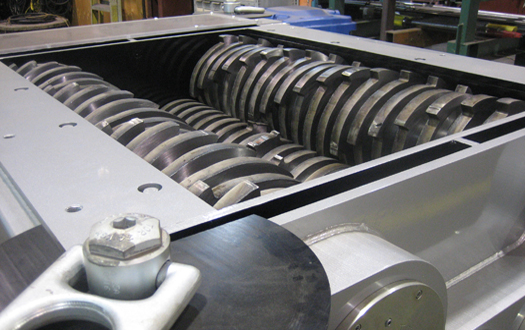

For larger recyclables, size reduction machines such as shredders, pulverizers, and granulators are essential to break down materials into smaller, more manageable pieces. While some areas require recyclables to be pre-sorted, many regions now accept unsorted materials to promote recycling. Consequently, various separation technologies have been developed to enhance efficient and accurate sorting. For instance, vibratory feeders can separate items based on weight, removing heavier objects like metals and glass. Additionally, magnetic separators and screens are used to systematically sort materials into distinct categories.

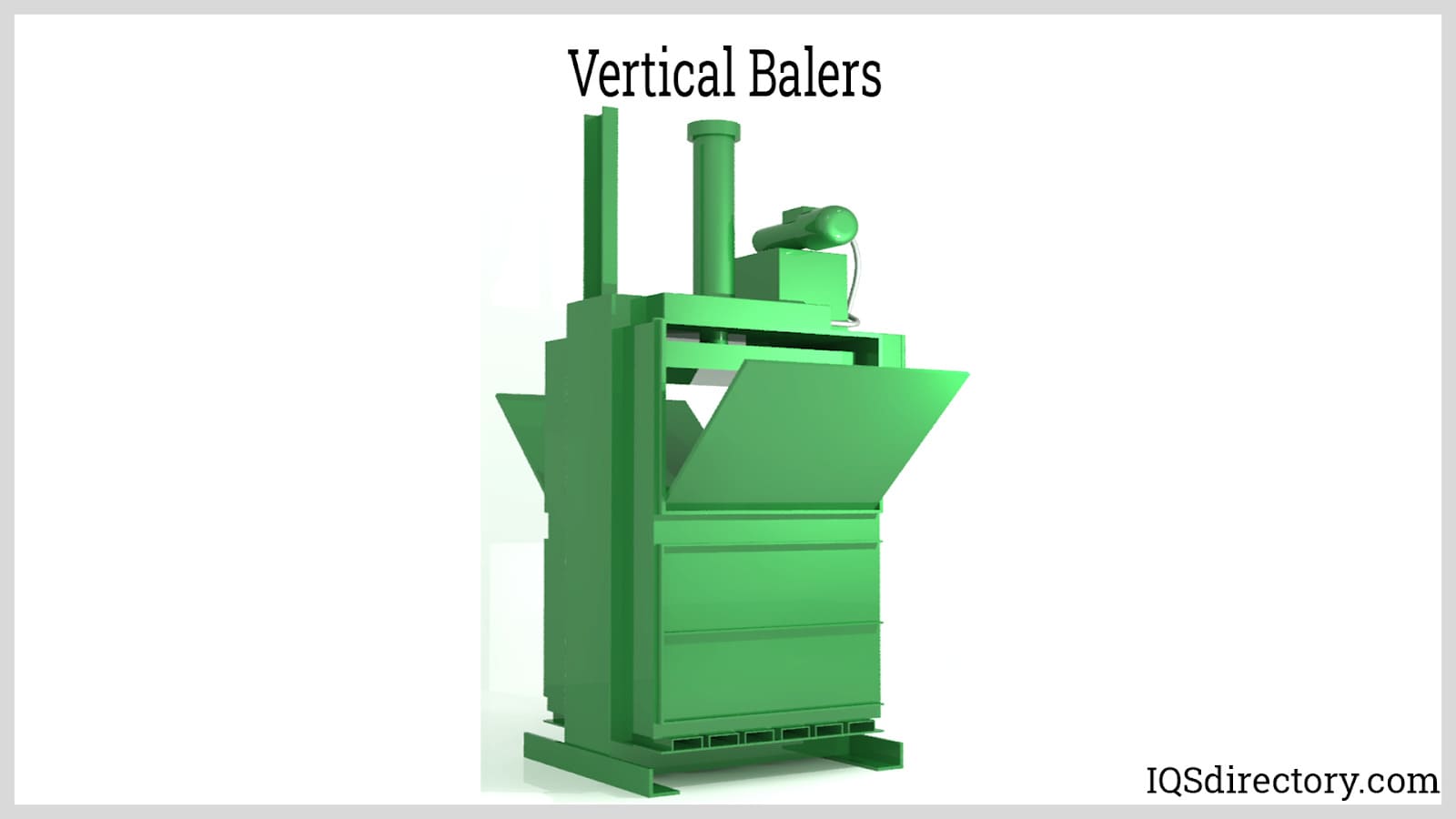

After separation, further processing may be required to prepare materials for reuse. The materials are then compressed into manageable bales using a baling machine. These bales are loaded onto trucks and shipped to factories for reuse in new products. For instance, a bale of crushed metal cans can be transported to a facility where the metal is melted and molded into new cans. At a mixed waste center, waste must be separated from recoverable materials. Most facilities can recover approximately 30% of the material, with the ongoing goal of increasing this percentage.

In the recycling sector, the term “recovery rate” denotes the proportion of materials that are effectively recycled and prevented from ending up in landfills. Although some waste is inevitably non-recyclable, enhancing this recovery rate is vital for protecting our environment and conserving resources. The limited nature of plastic, despite its extensive use, highlights the imperative to recycle as much as possible.

Creating products from recycled materials requires significantly less energy compared to using raw materials. For instance, manufacturing a plastic water bottle from recycled plastic consumes 88% less energy than producing it from new plastic. Similar energy savings apply to cardboard, wood, and glass products. Reusing materials enhances efficiency and reduces greenhouse gas emissions.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

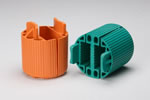

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services