Balers are used to push materials together and compact them so that they can be formed into bales, or block-like shapes, that are easy to stack and transport. In recycling facilities, recovered materials are put into a baling machine after being sorted. This way, entire bales of plastic or metal can be shipped to manufacturers to be melted down and reused for brand new products. Read More.....

Maren Balers & Shredders open_in_new

Location: South Holland, IL

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to generation of operators, service technicians and equipment buyers worldwide.

Harris Equipment open_in_new

Location: Cordele, GA

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

Excel Baler LLC open_in_new

Location: St. Charles, MN

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

SSI Shredding Systems, Inc. has manufactured industry proven shredder solutions globally since 1980. Our shredders are versatile, effective, and ready to be fully integrated into the waste reduction systems already present in your process. We offer a full range of single shaft, two shaft, and four shaft shredders as well as primary reducers and compaction solutions. Contact us today find the right solution today.

International Baler Corporation open_in_new

Location: Jacksonville, FL

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider our range of industrial compactors and related equipment. We carry a large variety of models. We can even customize a piece of baling equipment to fit a client’s specific needs. You will be surprised at the variety of options that fit your budget.

Some baling machines even come with the added feature of moisture extraction to remove residue that may be leftover. Cardboard, plastics and even metals may have been used as containers for liquids that leave traces on the material when it is going through the recycling center. Moisture extraction ensures that the bales are dry when they leave the facility.To begin creating a bale, a high volume of material is loaded into the input area of the machine. From this area, the material is led into a compression chamber where it is crushed and formed into a cube. Most balers are powered by electricity, but they use hydraulic power to compact and push material because this allows for a strong and consistent compressive force. After compaction, wire or strong plastic ties are then bound around the bale to hold it together while it is moved. Some balers can even be adjusted to create custom-sized bales. Since the bales are so heavy, a forklift is used to lift them and stack them or drive them directly onto a truck for shipping.For manufacturers in industries that use recycled materials to create new products, compact bales are very convenient. They can be stored for processing at a later time, and easily moved around a factory using a forklift. Most factories are at maximum efficiency during high production, so it is optimal to have large amounts of material that can be melted all at once.There are several types of balers, including:

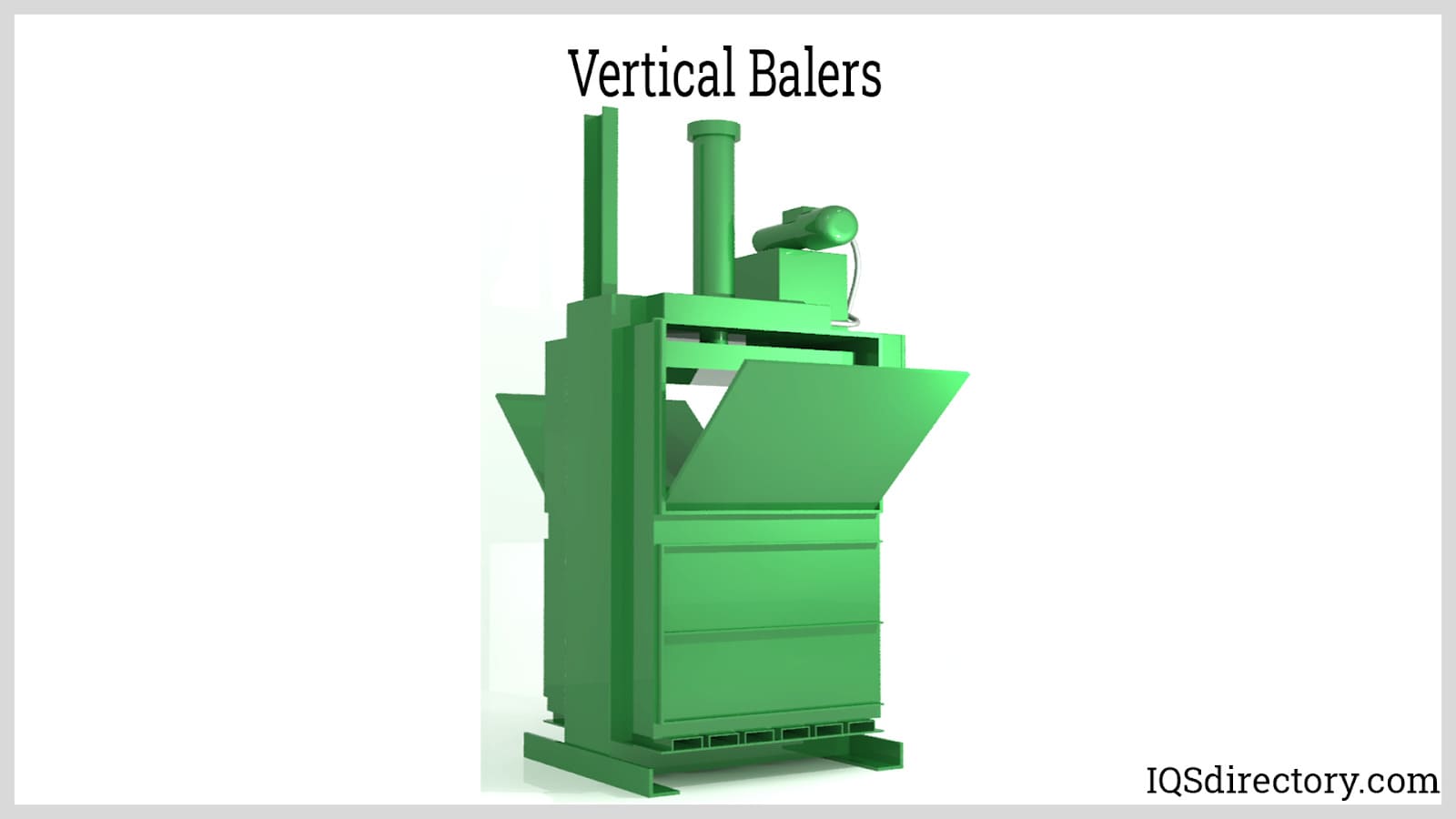

Vertical Balers

A vertical baler is a baling machine which utilizes a vertically oriented ram to compact recycled materials. Materials can be loaded in a variety of different ways, but most vertical balers are loaded through a large compartment on the front of the machine, which is then closed during operation. Since they are vertically oriented, they usually take up far less floor space than other baling options. They are usually less expensive as well. Vertical balers are most commonly associated with cardboard baling, but they are capable of baling many different types of recycled materials and can be customized to fit specific requirements.

Horizontal Balers

Horizontal balers are balers equipped with a horizontally acting compression ram. This kind of baler is usually much larger than a vertical baler but has the added benefit of handling larger quantities of materials at one time and can even operate continuously. Horizontal balers can be fed manually or can be equipped with automated systems like conveyors and feeders to continuously feed materials into the compression chamber. Applications which handle high volume recyclables usually take advantage of horizontal balers as they provide greater material handling efficiency. These balers can also be designed to handle practically any recycled material, from paper to metals.

Two Ram Balers

A two ram baler is a style of horizontal baler which uses two horizontally oriented rams instead of just one. These balers are typically fitted with larger hoppers and feeding mechanisms, so that they can more quickly feed material into the compression chamber. With two rams, the baler can effectively compress bulkier materials and larger quantities of materials. In some cases, a two ram baler can eliminate the need for shredding, pulverizing, and other conditioning processes. In general, two ram balers allow recyclers to process more material, faster. However, since they are using two rams, they do require more room and more power.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services