Recycling is all about getting used materials back into a workable state so that they can be formed for their new purpose. It takes special equipment to break different materials down into smaller, more malleable units. Granulating equipment is used in some recycling processes and systems to turn recyclable materials (especially plastics) into small pellets or granules. Read More…

Granutech-Saturn Systems

Here at Granutech-Saturn Systems we manufacture high performance equipment which can handle the toughest projects. Our Saturn Hammermills are engineered to meet the specific requirements of a variety of applications inlcuding metal recycling, waste-to-energy, electronic scrap, medical waste, bulky waste, and more. We are the experts of pulverizing technology with experience dating back to 1971. For more information visit www.granutech.com and see our PRODUCTS page.

Grand Prairie, TX | 877-582-7800

TerraSource Global

Crush, grind, granulate, shred, pulverize, de-lump - Whatever material processing you need, TerraSource Global has the equipment you`ve been looking for. Since we first opened our doors, TerraSource Global has provided pulverizers, wood grinders, feed & grain mills, lumpbreakers and custom products to a number of industries. Manufacturing expertise defines our business. Call today!

St. Louis, MO | 855-483-7721

Shred-Tech

Shred-Tech is an industry leader in the custom design and manufacturing of waste reduction systems and shredding machinery for a variety of recycling applications. Our Mobile and Stationary shredding solutions can handle a wide variety of materials including e-waste, plastics, paper and metals. We create pulverizers that are perfect for you. Contact us today of visit us online for more details.

Cambridge, ON | 800-465-3214

SSI Shredding Systems, Inc.

SSI Shredding Systems, Inc. is ready to suit your shredding, compacting and pulverizing needs. We have multiple reducers to choose from to meet your pulverizing requirements with ease. Whether you need a system that processes 1-150 tons per hour we can help you achieve your goals. View our products in action by watching our abundance of videos on our website. Call us with any questions or request more information from SSI today.

Wilsonville, OR | 503-682-3633

This makes it much easier to ship materials by weight and integrate them into new manufacturing process so that new products can be made by melting the granules back down and molding them.

This makes it much easier to ship materials by weight and integrate them into new manufacturing process so that new products can be made by melting the granules back down and molding them.Granulators can be built to process metals, rubber, plastics and more. The size of the granules that are produced can also be adjusted based on the piece of equipment that is used. The machine usually has a hopper area that leads into a series of sharp rotating teeth that crush and shred the material evenly, pulling it through to a depository beneath. Most granulators are used to process plastic materials because these will be taken to manufacturing plants and melted down for new products. If a uniform granule size can be created by the granulator, then the companies purchasing the plastics can weigh them out before production and have a high level of confidence in the precision of their material measurements before manufacturing.

A granulator is powered by an electric motor with a rotator that is attached to the head of the motor by a belt. The rapid spinning causes motion on the granulator rotor and pulls objects into the machine. Granulators are built with a wide variety of power options, from 5 to over 50 horsepower. The machine can easily be assembled on a warehouse floor and integrated into the rest of the recycling or manufacturing process. A conveyor can carry the raw plastics to the hopper of the granulator where they are dumped, and then continue to carry them on to packaging or storage bins after the plastic has been broken down. Fully enclosed granulators trap material in a chamber and prevent any granules from being flung out of the mechanism, reducing wasted plastic.

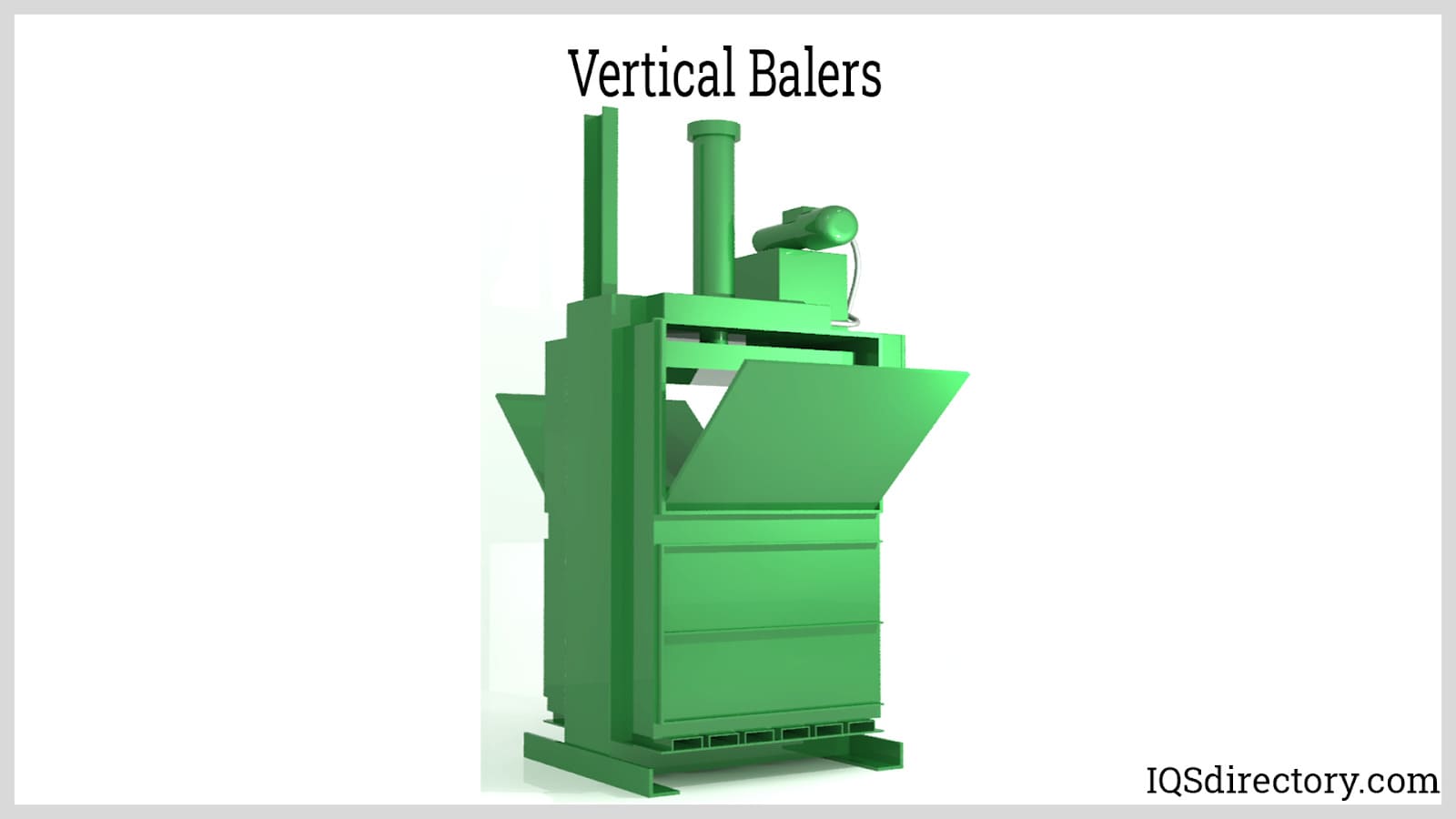

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services