A major problem facing the waste management industry is the decreasing amount of landfill space. Each year, the world produces millions of tons of disposable waste to be buried in a landfill. Regardless of the many measures taken to reduce the amount of waste, landfills continue to be filled. Read More.....

International Baler Corporation open_in_new

Location: Jacksonville, FL

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider our range of industrial compactors and related equipment. We carry a large variety of models. We can even customize a piece of baling equipment to fit a client’s specific needs. You will be surprised at the variety of options that fit your budget.

Harris Equipment open_in_new

Location: Cordele, GA

In Business for over 100 years, Harris has maintained its position as the industry leader by paying attention to its customers needs. Our vertical, horizontal and 2-ram balers process recovered papers, paperboard, plastics, solid waste and light ferrous and non ferrous metals. Harris supplies the right equipment for your application.

Excel Baler LLC open_in_new

Location: St. Charles, MN

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

SSI Shredding Systems, Inc. has manufactured industry proven shredder solutions globally since 1980. Our shredders are versatile, effective, and ready to be fully integrated into the waste reduction systems already present in your process. We offer a full range of single shaft, two shaft, and four shaft shredders as well as primary reducers and compaction solutions. Contact us today find the right solution today.

A major breakthrough in the ability to dispose of trash is the compactor, which was first introduced in the 1940s. A large percentage of waste material that fills landfills and garbage cans is made up of air and various gases. A volume of several hundred square feet can be reduced to under a hundred feet by crushing and compacting it. The crushing and compacting process removes the air and significantly reduces the size of the waste material.

The term "trash compactor" covers a wide range of devices that are designed to remove the air and gases from waste matter. Ones that are designed for the home are the size of an appliance and are installed in cupboards, under sinks, or placed in the basement. These smaller versions of a compactor can normally hold 30 to 40 lbs. of waste.

Commercial trash compactors are more common and are used by industrial operations to reduce their environmental footprint. With the rising concern for the environment, the majority of industries have instituted some form of trash compacting and recycling program. To assist in their efforts, trash collecting companies make large capacity trash compactors available for on-site use.

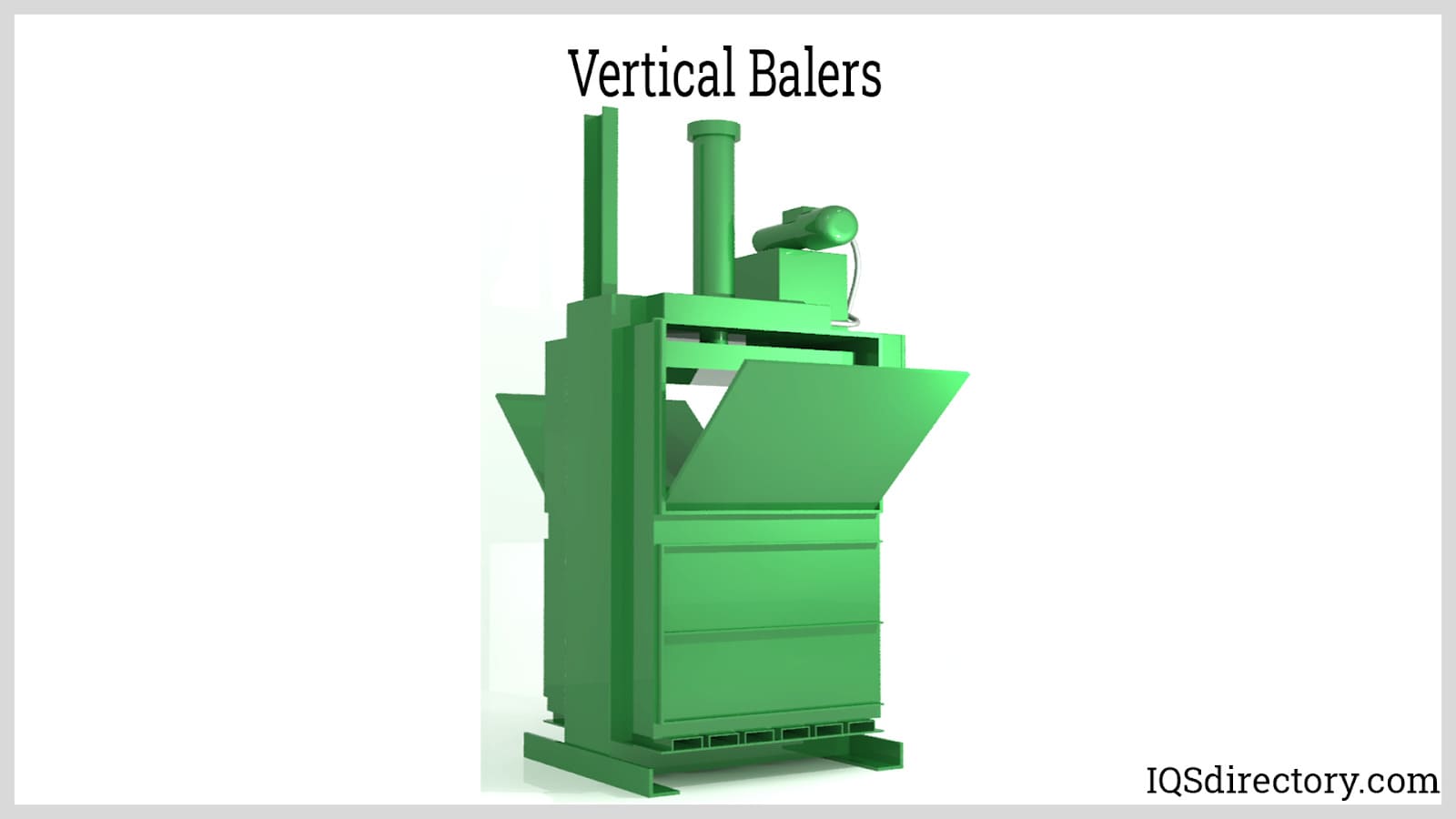

The basic purpose of a trash compactor is to apply a significant amount of pressure to waste material in a confined space to compress it into a solid cube or rectangular shape. The main part of a trash compactor is the ram that is used to compress and crush the waste material. The ram can be placed in either a horizontally above the trash chamber or vertically and is made of hardened steel with a flat surface that runs along tracks or guides. The process of compacting involves forcing the ram against the trash by a hydraulically or pneumatically driven piston.

A key factor for a trash compactor is the limitation of the amount of space between the ram and the sides of the enclosure to ensure that waste material does not escape. To ensure smooth operation of a compactor, ram tracks and guides are regularly checked for lubrication along with the hydraulic piston.

The size of a trash compactor depends on the industry where it is being used as well as the type of waste material. For offices and small businesses, smaller versions of trash compactors are used to crush and compact paper and boxes. For manufacturing operations, care is taken in determining the type of waste to be crushed to avoid any form of volatile or flammable materials.

When a commercial trash compactor is to be emptied, the complete unit is picked up and removed. For industrial operations, emptying and replacing of the trash compactor may happen daily or several times during the day depending on the volume of trash produced. Unlike a home or small office trash compactor, industrial trash compactors have an automated system for loading trash, which is connected to production or assembly operations.

With the growing concern for the environment and the need to limit the amount of waste poured into landfills, trash compactors will continue to become an essential part of conservation and waste management.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services